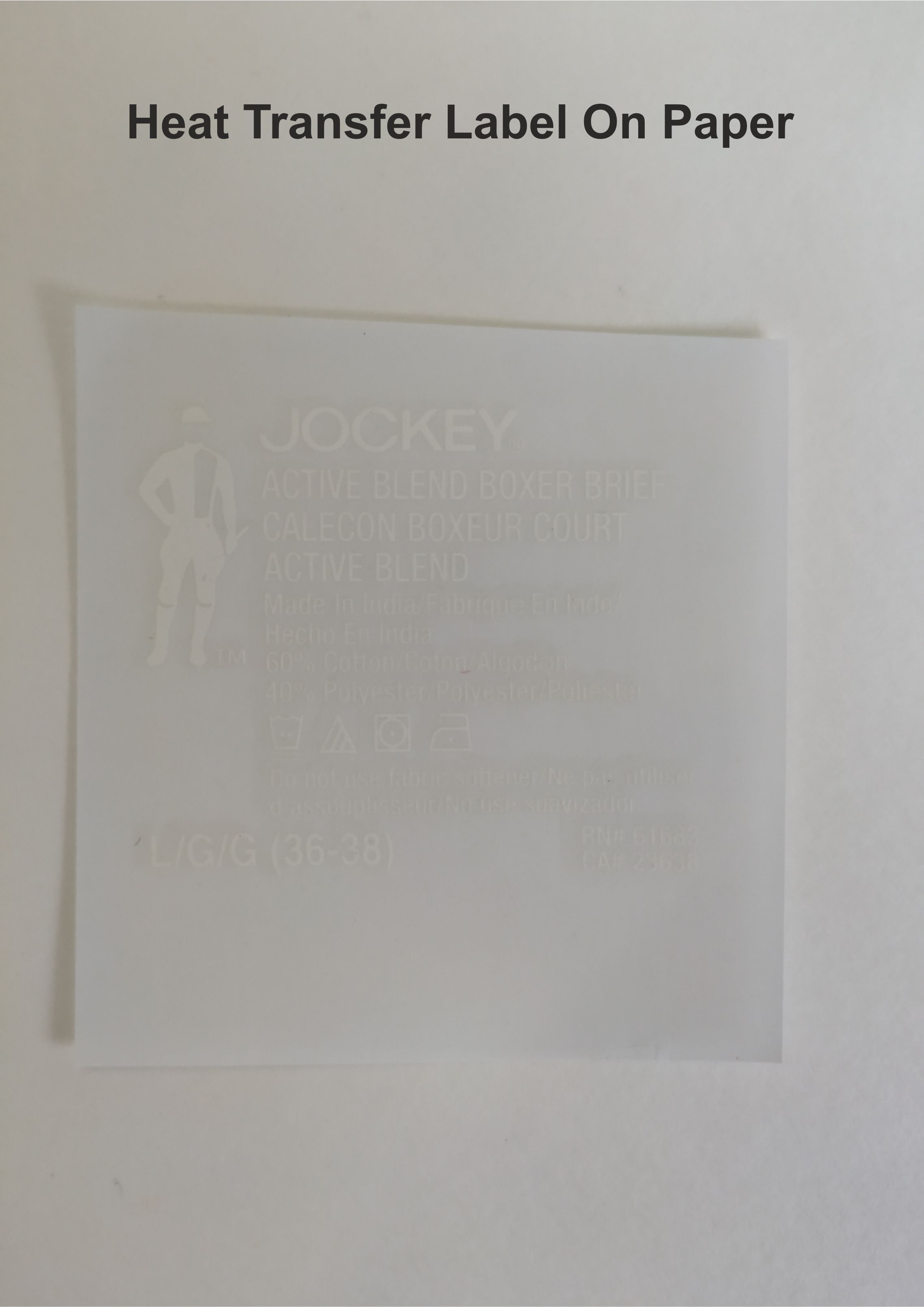

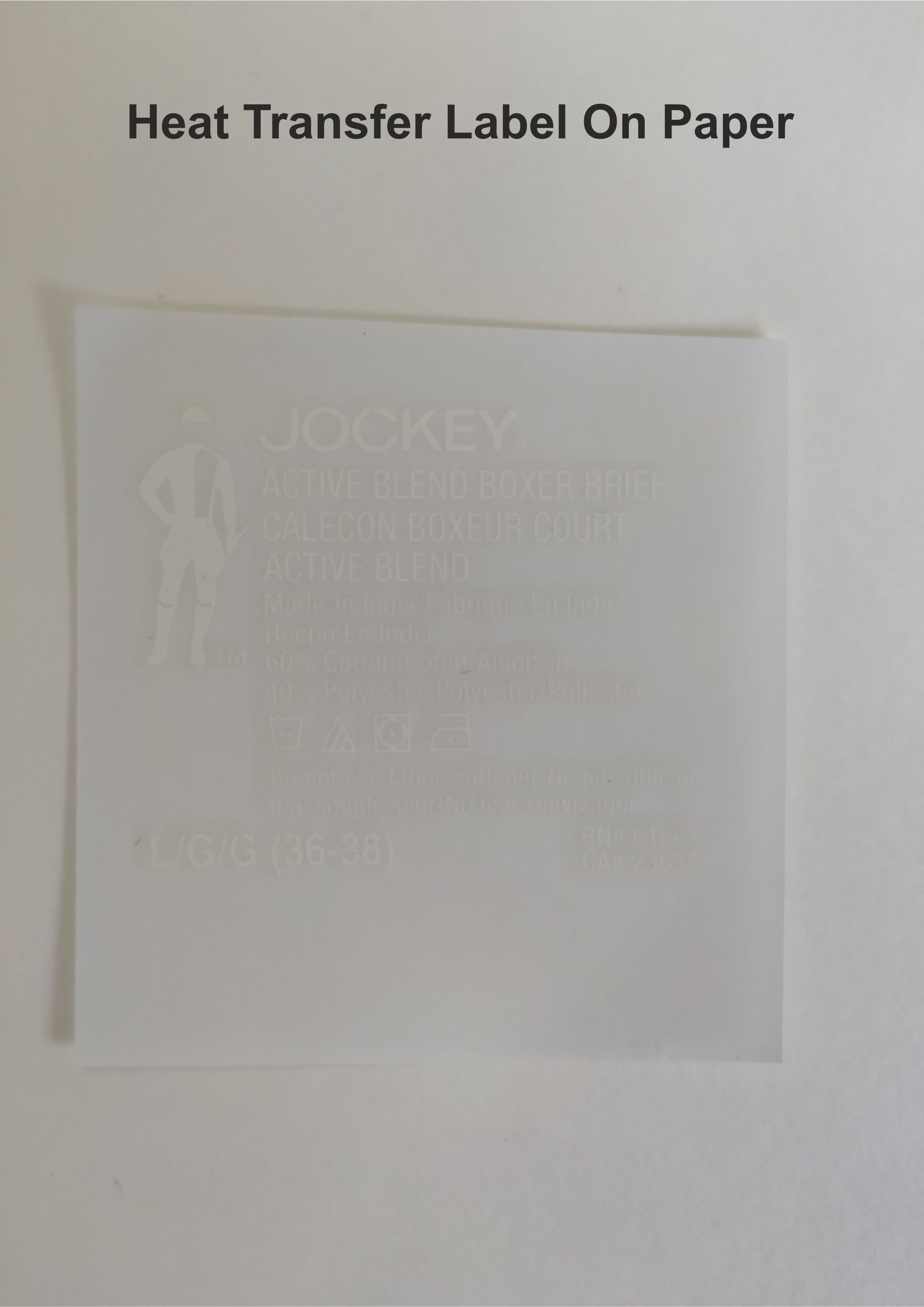

heat transfer labels

heat transfer labels Specification

- Print Type

- Digital, Screen, Offset

- Adhesive Type

- Heat Activated

- Surface Finish

- Glossy, Matte

- Printing Method

- Heat Transfer

- Water Proof

- Yes

- Pattern

- Customizable, Printed

- Features

- Soft feel, High durability, Fade resistant, Eco-friendly, Skin-friendly, Washable

- Usage & Applications

- T-shirt Labels, Care Labels, Brand Labels, Size Labels, Fashion Labels

- Shape

- Rectangular

- Material

- PET (Polyethylene Terephthalate) Film

- Use

- Garments, Apparel, Fabrics, Sportswear, Underwear, Lingerie, Kidswear, and Accessories

- Tape Type

- Single Sided

- Adhesive

- Non-Toxic Heat Sensitive Adhesive

- Design Printing

- Offset Printing, Rotogravure Printing, Flexographic Printing

- Color

- Transparent with Multi-color Print

- Length

- Customized, generally up to 100 meters per roll

- Width

- Customized, typically 10 mm to 200 mm

- Thickness

- 0.02 mm to 0.10 mm

- Style

- Modern

- Dry Cleaning Resistance

- Yes

- Temperature Range for Application

- 130°C - 150°C (266°F - 302°F)

- Wash Resistance

- Withstands multiple washing cycles

- Odor

- Odorless

- Peel Type

- Cold Peel or Hot Peel options available

- Ironing Resistance

- Can be ironed on reverse side

- Storage Condition

- Below 25°C, Avoid humidity & sunlight

- Suitable Fabrics

- Cotton, Polyester, Lycra, Blends, Synthetic

- Shrinkage

- Minimal, less than 2%

- Finish after Transfer

- No background residue, seamless integration

- Pressure Requirement

- 2.5 - 4 kg/cm² during transfer

- Transfer Time

- 8 - 15 seconds

- Eco-friendliness

- PVC-free, meets environmental safety standards

- Shelf Life

- Up to 12 months when stored in cool, dry place

heat transfer labels Trade Information

- Minimum Order Quantity

- 2000 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 100000 Pieces Per Day

- Delivery Time

- 8 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Asia, Central America, South America, Eastern Europe, Western Europe

- Certifications

- iso , okeotex

About heat transfer labels

Heat Transfers labels are mad with utmost care & it enhances the beauty of garment & is widely used in undergarment & t shirts . It givens exclusive look to the garment especially cotton garments.Advanced Label Performance

Our heat transfer labels utilize a PET film base and heat-sensitive adhesive, delivering fade-resistant prints with a soft feel and minimal shrinkage. Suitable for various printing methods like digital, offset, and screen, these labels can be customized for unique fashion, branding, and care labeling needs. Their glossy or matte finish, seamless application, and waterproof quality ensure premium performance on different apparel types.

Eco-Friendly & Safe Solution

Designed without PVC and using non-toxic adhesive, our labels comply with environmental safety standards. The material is safe for skin contact, making it suitable for kidswear and underwear. Eco-conscious manufacturers can rely on these labels for their commitment to sustainability and safety while maintaining high durability and modern style.

Simple Application & Versatile Use

Applying our heat transfer labels is efficient and straightforward, requiring only 8-15 seconds at 130C-150C with 2.5-4 kg/cm2 pressure. Labels are customizable in width and length to suit diverse garment types, from T-shirts to accessories. Their ability to withstand washing, dry cleaning, and ironing offers versatility and reliability in both domestic and industrial settings.

FAQ's of heat transfer labels:

Q: How do I apply heat transfer labels using the Cold Peel or Hot Peel method?

A: Heat transfer labels are applied by placing the label on the fabric and pressing at a temperature between 130C and 150C with a pressure of 2.5-4 kg/cm2 for 8-15 seconds. Cold Peel requires you to wait until the film cools before peeling, while Hot Peel allows immediate removal after heat treatment.Q: What types of fabrics are compatible with these heat transfer labels?

A: Our labels are suitable for a wide range of fabrics, including cotton, polyester, lycra, blends, and synthetic materials. They work well on garments, sportswear, underwear, kidswear, and fashion accessories.Q: What ensures the durability of these heat transfer labels in terms of washing and dry cleaning?

A: The labels are engineered to withstand multiple washing cycles and dry cleaning processes, retaining their print, color, and shape. They also allow ironing on the reverse side without damage, enhancing their longevity on various apparel.Q: Where should I store unused heat transfer label rolls to maintain shelf life?

A: Labels should be stored below 25C in a cool, dry environment, away from direct sunlight and humidity. Under these conditions, shelf life can extend up to 12 months.Q: Can I customize the design, color, and size of the heat transfer labels?

A: Yes, you can customize label width (10-200 mm), thickness (0.02-0.10 mm), and length (up to 100 meters per roll). Printing methods such as offset, flexographic, rotogravure, digital, and screen printing are available, supporting multi-color and custom printed patterns.Q: What are the key benefits of using PET-based heat transfer labels with non-toxic, heat-sensitive adhesive?

A: These labels offer a seamless, odorless, and soft integration with garments, maintaining skin safety and eco-friendliness. They're fade-resistant, waterproof, and leave no background residue for a modern finish-ideal for branding, care labels, and fashion statements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Printed Labels Category

plain transparent sticker

Price 0.30 INR / Number

Minimum Order Quantity : 1000

Eco Friendly : YES

Features : Soft Touch

Coating Type : WaterResistant

Finish Type : Smooth

Sequential Numbered Printed labels

Price 0.50 INR / Number

Minimum Order Quantity : 2000

Eco Friendly : YES

Features : Good Quality

Coating Type : WaterResistant

Finish Type : Smooth

hologram printed cloth labels

Price 1.5 INR / Piece

Minimum Order Quantity : 10000 Pieces

Eco Friendly : YES

Features : Good Quality

Coating Type : WaterResistant

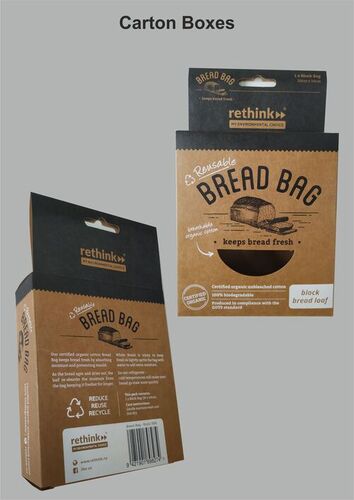

Paper Boxes

Price 12.00 INR / Number

Minimum Order Quantity : 1000

Eco Friendly : YES

Features : Soft Touch

Finish Type : Smooth